Soil Management: Principles of Soil Management

[addw2p name=”soilMgmtGeneral”]

Tropical environments provide unique conditions for the high yields of numerous crops, only if the right combinations of management, inputs and other factors influencing outputs per unit area and unit time are utilised (Pretty and Sanders, 1985). Soil management is one of the principal components of the above in the worldwide race between food production and population growth. Hence, it is not new and probably exists in tandem with the commencement of agriculture as recorded in writing dating back to 2500 B.C.

For many years, the main purposes of soil management are to maintain and improve soil fertility and synchronise soil productivity with and without enhancement, with crop requirements for high sustainable growth and yields. Therefore, we create soil conditions which are conducive to crop productivity (Kalpage, 1979) such as

-

good anchorage for crops,

-

ensure sufficient soil volume for rooting activity, and

-

supply adequate essential nutrients and water throughout each and every crop cycle.

These basic principles have served us well as shown by the present agricultural production which is in surplus worldwide although food distribution can be a problem.

Food surpluses have brought along not only low prices and cheap food policies which often favour politics (Johnston, 1995) but also concern for environmental pollution, soil degradation and non-sustainable agriculture. With increasing population and decreasing amount of land per capita, these threats can be real if our soils are ineptly managed. Thus, the present principles of soil management should encompass efforts to prevent such detrimental occurrences rather than a simple shift in paradigm to primarily tackle them. This is because the existence of mankind depends on an adequate supply of food and agricultural venture is a business concern.

We shall show that our present knowledge of plantation tree crops and soils has allow us to manage them in a sustainable manner and to do so in an environmentally acceptable way. This is probably central to our success in continuous cultivation of plantation tree crops on the same land at profitable level for many years.

Soil Management: General

[addw2p name=”soilMgmtGeneral”]

Introduction

The last 10 years saw a rapid expansion of land for plantation tree crops in south-east Asia, particularly in Malaysia and Indonesia. By 1993, Malaysia had 2.3 million hectares of oil palms, 1.8 million hectares of rubber and 0.4 million hectares of cocoa (Tay et al., 1995), which are growing by the days. Plantation tree crops are now cultivated on a diversified range of soils and landforms with increasing proportion of marginal soils. Our understanding of the physical, chemical and biological factors that control the fertility and productivity of soils has advanced greatly to allow us to exploit them effectively. In fact, an appreciation of this dynamic mechanism has led to an extensive use of soil information during this rapid expansion of oil palms in south-east Asia. The success story of our plantation industry owes partly to proper soil management practices, which evolved from both research and experience.

While good soil management has enable the continuous cultivation of plantation trees on the same land for over 3/4 of a century or after 3 generations of crops, poor soil management has dire consequences. For example, Goh and Chew (1994) showed that without manuring, the mean fresh fruit bunch (FFB) yield of oil palms was 32 t ha-1 yr-1 on Selangor series soil compared to 15 t ha-1 yr-1 on Rengam series soil. However, with manuring similar oil palm yields were obtained from both soil types. The increasing use of marginal land also dictates good soil management to ensure competitiveness and economic viability. This demands a correct identification of the types of soil limitations present and assessment of the degree of severity of each limitation in order to determine the most appropriate soil management practices required to fully exploit the yield potentials of the crops.

No agricultural system will be sustainable if it is not economically viable both for the farmer and the society of which he is a part (Johnston, 1995). Therefore, the importance of high early yields and sustainable yields from the economic stand point is obvious. Plantation tree crops being perennials, are subjected to large fluctuations in yields and prices of inputs and outputs. Coupled with the large investments and fixed costs involved in the industry, the maximum economic yield is usually at or near the site yield potential (Goh et al., 1994). There is now evidence to show that the inputs required to obtain the site yield potential do not necessarily endanger the environment, cause soil degradation nor reduce quality of the products (Chew et al.,1994a).

This paper, written in two parts, reviews the relevant soil management practices used in plantation tree crops for the humid tropics. Part one covers the general soil management practices while part two presents specific soil management practices to improve problem or marginal soils. This paper is restricted to oil palm, cocoa and rubber but the principles and practices should be applicable to most perennial tree crops.

Reference

Goh, K.J. and Chew, P.S. (1995). Managing soils for plantation tree crops. I. General soil management. In: Course on Soil Survey and Managing Tropical Soils (ed. Paramanathan, S.). MSSS and PASS, Kuala Lumpur: 228-245.

Note: The full list of references quoted in this article is available from the above paper.

Establishment: Concluding Remarks

Bearing in mind that an oil palm planting would have more than twenty years of productive life before it has to be replanted, the inputs at replanting and during the palm establishment period as mentioned in this article are highly justified. A well planted and well maintained stand of oil palm would reward the planter with sustainable high early and mature yields, provided the other agro-management requirements (such as nutrition, pest control etc. which are not discussed here) of the palms are also well taken care off.

Establishment: Costing

Typical costings (Rossi et al, Unpublished) of some of the above operations for the first 12 months are summarized in the table below:

|

Work Operations

|

Cost (RM/ha)

|

|||

|

Estate A

|

Estate B

|

Estate C

|

Average

|

|

| Legume planting |

252.00

|

260.68

|

173.30

|

228.66

|

| Holing and planting |

531.71

|

618.08

|

497.39

|

549.06

|

| Circle spraying |

107.99

|

96.65

|

155.11

|

119.92

|

| Spot spraying |

71.06

|

60.47

|

261.83

|

131.12

|

| Legume purification |

180.00

|

211.50

|

Not available

|

195.75

|

| Decreeping |

211.14

|

15.96

|

50.42

|

92.51

|

|

Total

|

1353.9

|

1263.34

|

1138.05

|

1317.01

|

Establishment: Weeding Operations in Immature Oil Palms

Weeds are plants growing in areas where they are not wanted and are more harmful than useful, even after their possible beneficial effects have been taken into account (Koch et al, 1983). Chung (1997) reported that since weeds can reduce crop growth and yield, interfere with harvesting, crop recovery and other agricultural operations, control measures are necessary.

According to Corley et al. (1976), the following four types of weeding operations will be necessary in areas where legume covers are maintained:

-

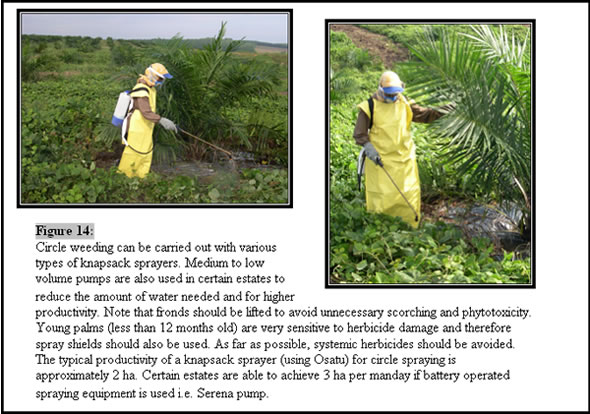

circle weeding of palm circles (Figure 14) – for young palms, circle weeding is normally carried out to prevent weed competition

-

strip weeding to provide access for harvesting and other field operations – more relevant for mature palms

-

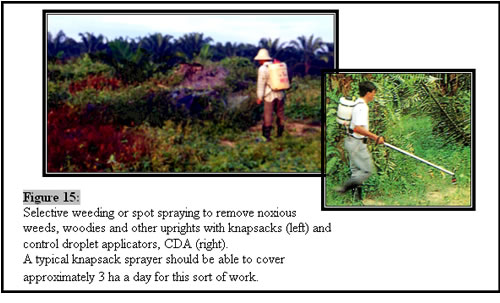

selective spot weeding to remove noxious weeds from the legume covers or natural ground covers (Figure 15 and Figure 16) and

-

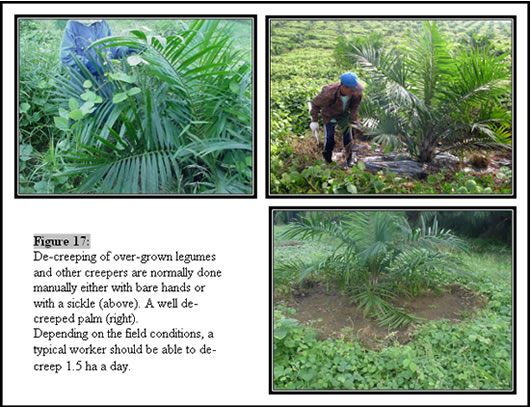

periodic control of legume covers if growth is too vigourous – de-creeping for example (Figure 17)

The various herbicide application techniques and their respective productivity are highlighted in Teoh (1991) and Chee and Chung (1998). The latter also recommended the types of herbicides to be used for controlling the different types of weeds.

Another necessary estate practice would be calibrating and checking to ensure the correct dosage of herbicides to be utilized for each equipment prior to the actual weeding work (Figure 18). It should be emphasized that the quality of herbicide application (correct dosage, proper usage of equipment and correct area of application) should precede that of quantity or productivity (how many hectares a person or equipment can do in a day) of applying the herbicides. It would be of no use spraying a large area but not getting the desired kill as inevitably, the job has to be repeated. The same principle should also apply to pesticide spraying i.e. controlling rhinoceros beetles with Cypermethrin.

With the usage of AA+ Mulch, better control of weeds and creepers is possible (Figure 19). Problems of phytotoxicity (Figure 21) and lower frond scorching are also reduced, as herbicide spraying is more easily carried out, thus promoting better palm growth (more leaf area with minimal scorching) resulting in high early yields. The AA+ Mulch would also be useful if planting is to be carried out in difficult areas such as in steep terrain areas, to reduce the need for frequent fertilizer applications and weed control (Figure 20) during the first year of planting.

With proper field upkeep i.e. timely and quality circle and spot spraying, the young immature oil palm field should look like Figure 22.

Establishment: Holing and Planting of Palms

The oil palms are preferably planted 1 month after the planting of legumes and the following are some of the normal planting operations:

-

lining (Figure 9)

-

holing (Figure 10)

-

final selection of nursery palms and transporting them to the field (Figure 11)

-

application of rock phosphates into the planting hole, removal of polybag and the actual planting (Figure 12)

-

firming up the base of the newly planted palm (Figure 12)

At palm planting, AA+ Mulch (Figure 13) with one year’s supply of fertilizer could also be utilized. Other benefits of this system would be discussed in section 4.0.

Establishment: Legume Planting

Besides protecting exposed soils (Figure 1) from risks of run-off and soil erosion, legumes play an important role in soil conservation in our humid tropics as exposed tropical soils weather rapidly, the soil structure deteriorates, the organic matter content decreases and nutrients are lost through leaching (Corley et al). Therefore, legumes are planted as soon as land clearing and preparation is completed to cover up the bare ground quickly. In addition, legumes also play a role in weed management (Chung, 1997) by smothering out the weeds.

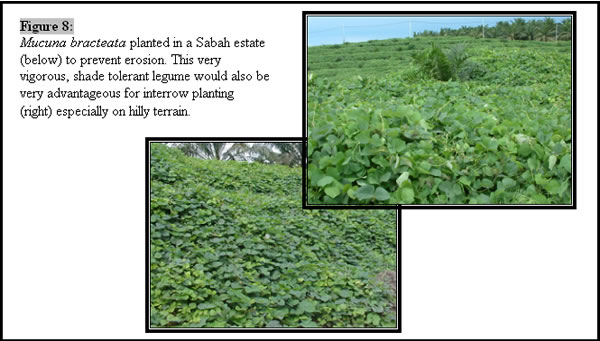

In addition, legume species planted in oil palm areas are able to produce large amounts of organic matter as well as fix large quantities of atmospheric nitrogen. The total biomass of conventional legumes (P. phaseoloides and C. caeruleum) at the end of the third year was 5.9 tons/ha and with newer species of legumes i.e. Mucuna bracteata (Figure 8), total biomass of 17.2 tons and 12.1 tons on flat and terraced land respectively, can be obtained (Chee and Chung, 1998). Other beneficial effects of legumes have been reported by Gray and Hew (1968) and Broughton (1977).

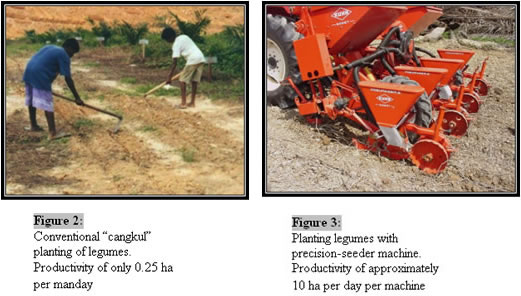

Planting of legumes has evolved from the conventional “cangkul” method to the more modern “precision-seeder” (Figures 2 and 3).

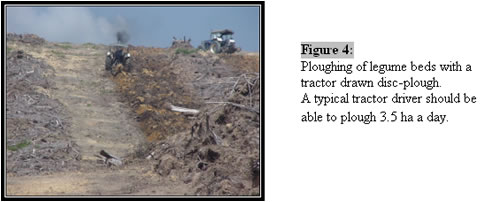

Prior to sowing of the legume seeds, ground preparation such as ploughing of legume beds with a tractor drawn disc-plough and harrowing is carried out (Figures 4 and 5)

.

Legume establishment is expedited with applications of rock phosphate and ground magnesium limestones (Figures 6 and 7).

Oil Palm: Establishment

TOWARDS THE ESTABLISHMENT OF A GOOD OIL PALM PLANTING

Introduction

Legume planting

Holing and planting of palms

Weeding operations in immature oil palms

Costing

Concluding remarks

Oil palms are normally planted after land clearing and land preparation work, which includes lining, holing and terracing if the terrain is hilly. In low-lying areas, drainage would also be necessary. In most oil palm plantings, leguminous cover crops are also planted in the interrows as they are able to establish and spread much faster than other vegetation. The legumes should preferably be planted prior to planting the palms but in many instances, due to timing and other constraints, the oil palms are planted first.

The immaturity period of the palms, which would normally last approximately 30 – 36 months where ablation is done, begins from the moment of palm planting. In areas where no ablation is done, this is reduced to 24 months. Most planters would deem the immaturity period as the period where extensive field maintenance is required e.g. circle spraying, spot spraying, decreeping, manuring, pest control etc. to ensure not only high early yields be obtained, but also mature yields. This article highlights some of the work that a planter has to plan and carry out at the onset of oil palm planting particularly those related to legume establishment, holing and planting of the palms and the subsequent weeding operations. This article also complements the other two articles in the previous two issues of this annual report.

Reference

Ng H.C.P. and Tan C. C. 2003. Towards the establishment of a good oil palm planting. Annual Report 2002. Royal Johore Planters’ Association : 22-30.

Note: The full list of references quoted in this article is available from the above paper.

Nursery: Summary of Recommendations

The selected area for a nursery should be on flat to gently undulating terrain, accessible with good road conditions and not prone to flooding.

The preparation of nursery area should be carried out through proper designing of nursery, clearing, fencing and lining.

The ordering of seeds should be scheduled appropriately over a period of time to ensure that adequate labour is available to handle each batch of seeds received and for field planting.

The selection of single or double stage nursery should be decided based on the area to be planted and the size of the nursery.

The nursery practices/maintenance including watering manuring, culling, pest and disease control and weeding should be closely supervised to ensure that all operations are on time and correctly implemented.

Herbicides and equipment for herbicides spraying should be clearly marked and stored separately from pesticides and foliar fertiliser to prevent contamination or incorrect chemical selection. Mistakes in this operation are usually costly and difficult to undo hence should be avoided at all costs.

Nursery: Maintenance

Watering

The most important factor in achieving good success in the nursery is the availability of sufficient water to ensure optimum growth of the seedlings. More often than not inadequate watering is the root of pest and disease problems in the nursery as the seedlings would be at a weaken stage and therefore more prone to pests and diseases. A good indication of inadequate watering in the nursery is the incidences of collante and blast disease.

Poor or uneven coverage of the irrigation system may also lead to seedlings of poor uniformity. This is a very common fault in nurseries. Watering must be done daily including holidays.

With the current technology of irrigation system in the nursery either by overhead sprinkler system (OSS) or lay flat sprinkler tubes (e.g. Sumisansui, photo 5 & 6), the watering should be carried out twice a day for 45 minutes each time, to supply 8mm of water daily. A rain gauge may be used to check whether the amount of water supplied is sufficient.

Manuring

It is well established that the fertiliser rates for nurseries require adjustment to varying management practices and according to different soil types (Hew & Toh, 1973). However the recommendations and system described in this paper are based on sandy clay loam, inland soils for general usage and on conventional fertilisers or controlled/slow release fertilisers.

Manuring programme based on conventional fertiliser

Fertilisers are not required until one complete new leaf has appeared (4 -5 weeks after planting). Use of conventional fertiliser should preferably be confined to small nurseries for field plantings of less than 50 ha or areas with adequate labour. The programme is given in Table 2 below:

|

Seedling age

|

Table 2. Conventional fertiliser manuring programme

|

||

|

(Weeks)

|

(Months)

|

||

|

Pre nursery stage

|

5-8

|

2

|

Weekly drench with a soluble foliar fertiliser (formulation of 22:22:10:1) at 15 g in 4 litres water for 100 seedlings.

|

|

9-12

|

3

|

Weekly drench with a soluble fertiliser (formulation of 22:22:10:1) at 15 g in 4 liters water for 25 seedlings.

|

|

|

Main nursery stage

|

13 – 16 (transplanting) |

4

|

Mix 100g RP/bag in soil medium for large bags. After transplanting no solid fertiliser application for 4 weeks but continue weekly fertiliser drench as for 3rd month

|

|

20

|

5

|

5 g CCM45/bag. If seedlings are chlorotic, continue weekly foliar drench as for 3rdmonth. Drench with HGFB solution*

|

|

|

24

|

6

|

10 g CCM45 and 10 kieserite/bag

|

|

|

28

|

7

|

15 g CCM45. Drench with HGFB solution*

|

|

|

32-39

|

8-9

|

20 gm CCM45

|

|

|

40-47

|

10-11

|

30 g CCM45

|

|

|

48

|

12

|

35 g CCM45

|

|

|

>52

|

>13

|

30 g CCM45 + 15 g kieserite

|

|

*Dissolve HGFB48 at 1 g/10 litres water for 7 months old and younger seedlings. For seedlings of 8 months and older, use a rate of 3g /10 litres water. The seedlings should be drenched with the HGFB solution at a rate 500ml/seedling.

Fertiliser application

For foliar application, the drenching of the seedlings with foliar fertiliser solution should be carried out early in the morning or late afternoon. As far as possible, the whole seedlings should be wetted and no watering of the seedling should be carried out for the day of application. However High Grade Fine Borate Compound ( HGFB ) solution application for large polybags should be done after normal watering.

For solid application, the compound fertiliser should be weighed to obtain the correct rates, and calibrated applicators (e.g. scoop, spoon, etc.) given to the workers to ensure that the correct rates are applied. The fertiliser should be evenly distributed on the surface of the polybag soil at least 2-4 cm away from the base of the seedlings. The application of solid fertiliser should be carried out when the seedlings are dry, i.e. in the morning before watering, or in the afternoon after the morning watering.

Good supervision of all fertiliser applications is necessary to obtain full benefits from the inputs.

Manuring programme based on slow release fertilisers

There are many types of slow release fertiliser (SRF) currently available in the market. The SRF selected for use should supply the required nutrients at the right time and amount to the seedlings for good growth.

Fertiliser rate

The general recommendation for use of SRF in the nursery is provided in Table 3 .

|

Seedling age

|

Table 3. Slow release fertiliser (SRF) manuring programme

|

|

|

(Weeks)

|

(Months)

|

|

|

1 – 12 |

3

|

Follow manuring programme for conventional fertilizer or 7.5g SRF per seedling

|

|

16 |

4 |

75 g SRF per seedling

|

|

20

|

5

|

15 g kieserite. Drench HGFB at 5th & 7 month.

|

|

40 – 48

|

10 – 12 |

30 g CCM45/seedling/mth.

|

Fertiliser application

The SRF should be spread evenly and buried at 10 cm below the soil surface.

Supplementary fertilisers should be applied from the 9th month onwards or even earlier if the seedlings show symptoms of deficiencies like yellowing, etc.

Corrective fertiliser application

With the use of SRF, it is essential to monitor the colour and growth of the seedlings regularly due to the long interval without any other fertiliser application. In cases of wrong or inadequate application as indicated by seedling colour and vigour, fertiliser supplementation is required as per conventional fertiliser programme for the appropriate seedling age provided in Table 2.

Culling

Culling is one of the most important procedures to be carried out in the nursery to ensure that only the most uniform and vigorous palms that are likely to give the highest yields are planted in the field.

Four rounds of culling are recommended during the nursery period. In addition, a final round of selection should be done just before field planting.

Culling in the pre-nursery stage

Culling at the pre-nursery stage is carried out at month 2 and prior to transplanting the main nursery at around month 3 to 4.

This is one of the main advantages of the double stage nursery system where the first stage culling of undesirable palms can be done stringently and quickly over large number of young seedlings. The main types of undesirable seedlings (should be culled) at this stage are as follows: narrow (grass leaf), rolled leaf, twisted leaf, crinkled leaf, collante and stunted or weak (runts) palms. Allow for 10 to 20% culling at this stage.

Culling in the main nursery

Culling in the main nursery should be carried out when the seedlings are 7 months and 9 months old while the fronds of neighbouring palms have not started to overlap and etiolation not set in to mask the runts. The typical characteristics of abnormal seedlings in the main nursery are as follows: –

Erect, flat top, broad pinnae, narrow pinnae, wide internodes, juvenile (slow to pinnate), weak and slow growing (runts), crinkled leaf, collante, chimaera, badly diseased (helminthosporium, curvularia, blast, crown disease) and palms badly damaged by chemicals.

The final round of selection based on uniformity and vigour should be carried out just before the seedlings are being loaded onto lorries/tractors for transport into the field. If planting is delayed the final round of culling must be carried out before etiolation sets in. Allow for 5 to 10% culling and selection for the main nursery.

Timely culling rounds will ensure the unnecessary keeping of unwanted seedlings and reduce costs in the nursery.

Recording

Accurate records of discarded seedlings are necessary to ensure that adequate seedlings are available for field planting and supplies.

Pests and Disease Control

This is another important aspect in oil palm nursery management. Pest infestations and disease infections can cause alarming damage and losses if not recognized at an early stage and brought under control quickly. Most pest and disease problems can be avoided by correct agronomic and management practices, but where they are unavoidable, early detection and prompt control measures are crucial.

Common pests and diseases in the nursery

Common pests in nursery are red spider mites, leaf-eating caterpillars, cockchafers, grasshoppers and rats. The common diseases are mainly fungal leaf diseases like curvularia, cercosporium and helminthosporium.

Pest and disease control

There are a number of measures which if implemented can assist in reducing the incidence and severity of pest and disease attack in the nursery. The key to good P and D control is vigilance and prompt action to contain the problem.

Prophylactic spraying

Routine prophylactic spraying is not necessary if the seedlings are growing vigorously and the nursery is well managed.

However, where nursery palms are sub-optimal in growth and vigour, fortnightly prophylactic spraying of fungicides and insecticides may be carried out until palms return to normal growth.

Pesticides may be mixed with foliar fertilizer mixtures in a single application but these should be confirmed with the supplier if in doubt.

Spraying should preferably be carried out in the evening after the last watering.

Training of nursery workers in pest and disease recognition

It is certainly worthwhile to train nursery workers to recognise the symptoms of common pests and diseases in the nursery and report them. This outbreak reports by people who are working full-time in the nursery will provide an “early warning” system to the management.

Weeding

Weeds in the nursery area should be eradicated since some weeds may harbour pests or are hosts for diseases. It is necessary to keep the polybags completely free of weeds that would compete for nutrients, moisture and sunlight. Ideally the nursery should be weed-free.

Weeding in the pre-nursery stage

In the pre-nursery where seedlings remain for only 12-16 weeks, very little weeding is required. When necessary, hand weeding in the inter-bed paths and within the small polybags should be carried out monthly.

It is generally recommended that all herbicides be avoided at this stage in view of the fact that any error can lead to serious seedling damages or losses.

Weeding in the main nursery stage

Mulching with palm kernel shells can greatly suppress the growth of weeds in the large polybags and any weeds appearing can be quickly and easily hand-weeded.

However, weeds on the ground and surrounding nursery area should be eradicated through chemical spraying as and when required. Only contact herbicides eg. paraquat should be used.

Storage of Chemicals and Equipment

The control of chemicals in the nursery is of the greatest importance. Many instances have occurred of herbicides being incorrectly utilised by mistaking them for insecticides or fungicides. In view of this problem it is strongly recommended that the estate have a separate nursery store and within the store, herbicides are kept separated from pesticides/foliar fertilizers in lockable cupboards. It is also important that nursery equipment used for spraying pesticides and herbicides be also clearly marked and kept apart in separate storage compartments to avoid costly mistakes of cross contamination. They should only be used in the nursery. Empty herbicide and pesticide containers should be discarded and not reused.