Precision Farming: Applicability of Precision Farming for Oil Palm Plantations

[addw2p name=”precisionFarming”]

The tools and technologies associated with precision farming have attracted the interest of researchers in the oil palm industry in Malaysia as illustrated by a number of recent papers such as Tey et al . (2000) on GIS, GPS and remote sensing, Goh et al. (1997) and Guha and Guha (1997) on decision support system, McMorrow et al. (2000) on remote sensing, Goh et al. (2000) on spatial FFB yield variation and Kok et al.(2000) on site-specific agronomic management. These tools and technologies provide an opportunity to understand and capitalise on the variabilities in the fields which have long been recognised by the planters but little can be done until now.

The existence of variabilities in oil palm plantations

Precision farming is only applicable if manageable variabilities exist in the fields. Two types of variability are of interest, namely, FFB yield which is the single most important factor influencing profit (Ong, 2000; Goh and Chew, 2000) and soil fertility which affects fertiliser input, the largest cost item.

a) FFB yields

The inherent palm to palm variability of FFB yield of oil palm has been studied via uniformity trials since the 1920s when it was first grown commercially. Its coefficient of variation (CV) could exceed 30% (Webster, 1938; Chapas, 1961; Goh and Alwi, 1988; Soh et al. , 1989). These CVs also vary from site to site and temporally (Goh and Alwi, 1988; Soh et al. , 1989). Part of the FFB yield variability could be attributed to soil heterogeneity where the Fairfield Smith’s heterogeneity index, “b”, commonly ranges from 0.25 to 0.93 (Goh and Alwi, 1988). Thus, Planters have demarcated their land into smaller management units or zones of 10 to 100 ha for more uniform fields and ease of implementing the agro-management practices.

However, the CV is non-spatial and does not distinguish between autocorrelated yield variation (which is manageable), and uncorrelated (‘nugget’) variation (which is not manageable) (McBratney et al. , 2000). This has prompted Goh et al. (2000b) to use geostatistical method to study the FFB yield variation in a fertiliser response trial of about 25 ha where FFB yields of individual palms were recorded. Results showed that the mean random (nugget) variation accounted for only 26% of the total variation (Table 2). About 74% of the FFB yield variation could be managed spatially if its causative factors are known.

Table 2: Semivariance analysis (standardised) of FFB yields of oil palm without N and K fertilisers from 1991 to 1998

| Parameter |

1991 |

1992 |

1993 |

1994 |

1995 |

1996 |

1997 |

1998 |

Mean |

| Total |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

| Nugget |

0.23 |

0.28 |

0.28 |

0.28 |

0.22 |

0.27 |

0.28 |

0.22 |

0.26 |

| Spatial |

0.77 |

0.72 |

0.72 |

0.72 |

0.78 |

0.73 |

0.72 |

0.72 |

0.74 |

| Range (m) |

15 |

21 |

12 |

18 |

15 |

9 |

15 |

21 |

16 |

After Goh et al . (2000b)

b) Soils

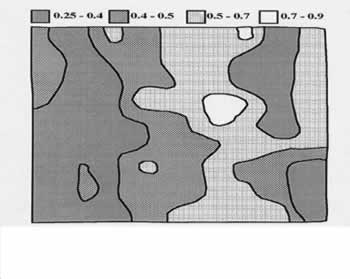

Malaysian soils have generally low soil fertility and hence, large responses to fertilisers are commonly obtained in the oil palm plantations (Gohet al ., 1999). Apart from this, the soil nutrient contents vary considerably (CVs commonly exceed 40%) even within the same soil series as shown by Ng and Ratnasingam (1970) and Law and Tan (1977) for Peninsular Malaysia and Goh et al. (1998) for Sabah. Ng and Ratnasingam (1970) further showed large variations and spatial patterns of nutrient contents for individual soil types e.g. exchangeable K distribution (Figure 4) in a 11 ha field of Selangor series soil, which was derived from marine alluvium and considered to be fairly homogenous by soil profile examination (Chew, 1998). Their results indicated that two-third of the field would not require K fertiliser while the balance, mainly in the western halve, would need low K fertiliser rate to sustain growth and production.

Figure 4: Distribution of exchangeable K values (cmol(+)/kg soil) in 11 ha oil palm field of Selangor series soil (source: Ng and Ratnasingam, 1970)

Soil variations could also arise from previous planting practices such as fertiliser application areas, frond placement and harvesters path (Kee et al. , 1995; Goh et al ., 1996). Goh et al . (1996) also found high spatial variability within micro-sites of palm circles, frond piles and interrows within single palm areas from previous fertiliser application practices with resultant nutrient patches within 2 m of each other (Table 3). There are many other known sources of soil variation such as micro-relief and these will not be discussed in the paper.

Table 3: Score of nutrient patches around individual oil palms on Musang series (Typic Paleudult) soil

|

Soil depth |

Site |

Fertiliser |

|

|

Without |

With |

||

|

0-15 |

Palm circle |

8 |

12 |

|

Interrow |

8 |

6 |

|

|

Frond heap |

15 |

12 |

|

|

15-30 |

Palm circle |

12 |

12 |

|

Interrow |

7 |

6 |

|

|

Frond heap |

11 |

12 |

|

Note: Maximum score of 15 for best soil fertility and minimum score of 5 for poorest soil fertility

Source: Goh et al . (1996)

Tee (Unpublished) has studied the nature of soil NH4+ -N and NO3– -N in a long-term fertiliser response trial in Sabah, Malaysia where N fertiliser was applied in the palm circle (within 2 m radius of the palm). She found that the inherent soil NH4+ -N and NO3– -N i.e. in areas without nitrogen application for the past 10 years had higher CV compared to manured areas (Table 4). However, the CVs in the latter sites were still large with 45% for NH4+ -N and 81% for NO3– -N. But surprisingly almost all the variations were spatially related (Table 5) and therefore, manageable. The spatial ranges for NH4 + -N and NO3– -N were also substantially reduced with manuring. Interestingly, the spatial range for NH4+ -N in manured areas was 51.4 m, which was equivalent to 5 to 6 palm distance and corresponded well to the experimental plot size. Further work is necessary to ascertain and understand the results.

Table 4: Mean and variation of soil ammonium- and nitrate-N in the palm circle of oil palm on Kumansi Family soil in Malaysia

| Nitrogen | Nutrient |

Mean (mg/kg) |

CV (%) |

| Without |

NH 4 -N |

27.2 |

54.9 |

| With |

NH 4 -N |

140.9 |

44.8 |

| Without |

NO 3 -N |

7.5 |

102.5 |

| With |

NO 3 -N |

9.7 |

80.5 |

Note: CV denotes coefficient of variation

After Tee (Unpublished)

Table 5: Nature of variations of soil ammonium- and nitrate-N in the palm circle of oil palm on Kumansi Family soil in Malaysia

| Nitrogen | Nutrient |

Total Variation |

Random |

Spatial |

Range (m) |

| Without |

NH 4 -N |

2.44 |

0.18 |

2.26 |

254.3 |

| With |

NH 4 -N |

1.06 |

0.09 |

0.97 |

51.4 |

| Without |

NO 3 -N |

1.23 |

0 |

1.23 |

71.6 |

| With |

NO 3 -N |

1.02 |

0.06 |

0.96 |

19 |

After Tee (Unpublished)

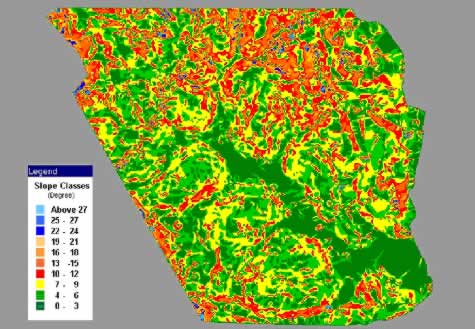

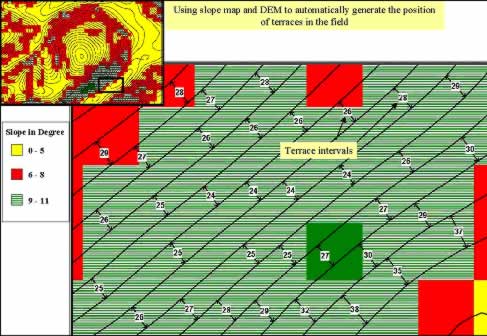

Maximising FFB yields

The major factors affecting oil palm yield are known and their effects have been quantified by various researchers such as Foster et al . (1985) and Kee et al .( 1994). Goh et al. (2000a) presented an outline of an empirical model called ASYP, which has been validated (Kee et al ., 1994; Kee et al ., 1999) and used commercially as shown in Figure 5. The model predicted that site yield potential of a field is more or less predetermined after planting. Very little can be done to change the variable factors such as planting density and pattern till replanting more than 20 years later (Chew, 1998). Uneven planting with over-crowded spacing or high vacancies particularly in hilly, rugged terrain (Figure 6) can result in poor uniformity of growth, light utilisation and exploitation of soil nutrients and water for maximum production. This common problem provides an excellent opportunity for precision farming by making full use of remote sensing and digital elevation model (DEM) to demarcate the terrain as shown in Figure 7 and coupled with soil maps for specific practices such as higher planting density for peat soil (160 palms per ha) and shallower soils (148 palms per ha). We can also automatically generate precise positions of the terraces for constant density planting in hilly areas as illustrated in Figure 8 (Tey et al ., 2000). The latter has always been a Planter’s dream but could be a reality now with the new tools and technologies.

Figure 5: Primary factors influencing the site yield potential of oil palm in Malaysia

Source: Goh et al. (2000a)

Figure 6: Ikonos remote sensing image (1 m resolution) shows areas with large vacancies and uneven plantings.

Source: Space Imaging Inc., Singapore.

Figure 7: A 5 meter-pixel slope map derived from the DEM of the study area allows the demarcation of field by terrain.

Source: Tey et al . (2000)

Figure 8: Using DEM and slope map to automatically generate the proposed terraces for constant density planting in oil palm plantation

Source: Tey et al . (2000)

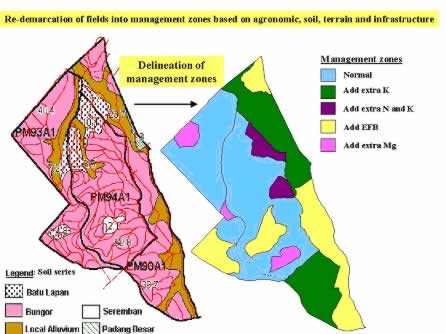

The soil factors in the production equation of oil palm (Figure 5) could be easily determined by detailed soil survey (Goh et al ., 1997). This traditional process is essential for maximising FFB yields because the different marginal and problem soils in the oil palm plantations would require separate management strategies and agricultural practices (Goh and Chew, 1995) as shown in Figure 9. Of more importance is perhaps the identification of specific, main soil and agronomic limiting factors (e.g. shallow, lateritic soils) and reclassification of common soils in each field into practical management zones that are bordered by roads and precisely located in GPS maps for ease of implementing the prescribed remedial actions (Figure 9). The impact of site-specific management was demonstrated by Goh et al. (1997) in a semi-commercial trial where each field was separated into lateritic and non-lateritic areas in 1986 (Table 6). The overall FFB yield of the 216-ha area increased from 18.4 t/ha/yr in the period of 1984-86 where uniform management was practised to 26.3 t/ha/yr in 1990-92 after implementation of site-specific inputs from 1986 (Kok et al ., 2000). At palm oil price of RM 1000/tonne, profit per hectare was 35% better in the period after site-specific management (Goh et al ., 1997).

Figure 9: Creation of practical management zones for site-specific agricultural practices

Adapted from Kok et al. (2000)

Table 6: Effect of improved agromanagement inputs and site-specific management on FFB yields

|

Details of site |

FFB yield (t/ha/yr) |

||||

| Field | Soil type |

Site yield potential (t/ha/yr) |

Period 1

|

Period 2 |

Period 3 |

| PM81A | Non-lateritic |

32.6 |

19.6 |

30.1 |

32.4 |

| PM81B | Non-lateritic |

28.6 |

15.8 |

26.7 |

28.0 |

| PM82 | Non-lateritic |

30.1 |

17.3 |

33.0 |

32.8 |

| PM77 | Non-lateritic |

30.2 |

19.3 |

29.3 |

28.0 |

| PM72 | Non-lateritic |

27.0 |

19.0 |

25.0 |

25.0 |

| Weighted mean |

28.6 |

18.4 |

27.9 |

27.6 |

|

| PM81A | Lateritic |

26.8 |

19.6 |

25.1 |

30.6 |

| PM81B | Lateritic |

23.4 |

15.8 |

22.5 |

25.8 |

| PM82 | Lateritic |

26.7 |

17.3 |

25.2 |

28.0 |

| PM77 | Lateritic |

25.6 |

19.3 |

24.0 |

25.4 |

| PM72 | Lateritic |

23.1 |

19.0 |

21.7 |

22.9 |

| Weighted mean |

24.4 |

18.4 |

23.0 |

25.1 |

|

Note: Uniform management of each field in period 1. Site yield potential of each site was estimated using ASYP model in 1986.

After Goh et al. (1997)

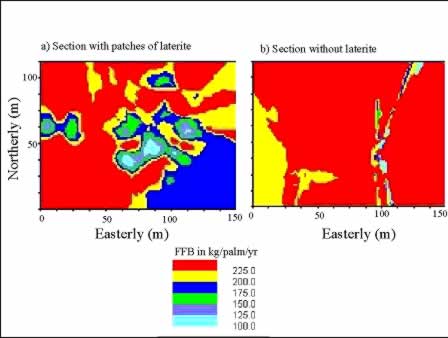

The management zones can be further delineated if FFB yield maps are available as shown in Figure 10. Even in a relatively uniform field with similar management practices, there are distinct areas of high and low yielding palms, e.g. a patch of low yielding palms in the lower right-hand corner of Figure 10a and western corner of Figure 10b.

Figure 10: FFB yield maps of oil palm in 2 different sections of a relatively uniform field

Source: Tee (Unpublished)

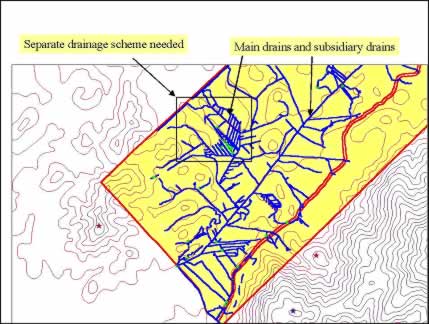

Quick identification of problems and nipping them in the buds are key steps towards maximising FFB yields in the plantations. Two examples are provided in the paper. Firstly, we have used GIS and GPS to improve drainage in an estate (Tey and Chew, 1997). This problem requires an overview of the watershed on a regional basis which is commonly beyond the estate boundary and covers land owners. With the new tools, we can easily compute the volume of excess water to drain, determine the direction of main drain, design a system of collection and field drains and compartmentalise areas for specific drainage design (Figure 11).

Figure 11: Design of drainage system in an oil palm plantation using GIS, GPS and DEM

Adapted from Tey and Chew (1997)

Another example is the assessment of the extent and progress of pest damage in an oil palm plantation using remote sensing images (Figure 12) where the ability to survey affected areas quickly is a big advantage in pest and disease management (Chew, 1998). We can also identify the direction of the pest movement, which is easterly in the example, and the focal points where the next outbreak is likely to occur. This allows for differential treatments and timing of treatments to contain and ultimately eradicate the pest.

Figure 12: Quick assessment of pest damage and movement using remote sensing image

Adapted from McMorrow and Tey (2000)

Optimising inputs through precise actions

a) Management zone

The current technologies, information and management level at the oil palm plantation do not allow the precise management of single oil palm. Therefore, creation of management zones within the plantation based on palm age, agronomic and soil information and infrastructure is still the most effective means to optimise inputs as discussed earlier. The difficulty here is to decide on the scale or size of each management zone, which is probably too big now at 10 to 100 ha. Early work shows that the spatial variation of FFB yield is isotropic with a range of about 3 palm distance (Goh et al ., 2000b). This means that the optimum size of a management zone is 32 palms given the triangular spacing in oil palm planting. But with the common road spacing of 20 palm distance, the minimum, practical management size should be 140 palms (7 palm rows x 20 palms per row) or about 1 ha. Further work is needed to ascertain this.

b) Fertilisation

The principal agronomic constraint to high productivity is usually inadequate soil nutrient supply (Chew, 1998), which is corrected by large amount of fertilisers. Thus, fertiliser is the largest cost item in the production of oil palm in Malaysia. It constitutes about 60 – 70% of the field upkeep cost of oil palm. Chew (1998) further contended that “Wrong fertilisation techniques may result in high financial losses through loss of crop or excessive fertilisation and risks of high nutrient losses in run-off, leaching and other nutrient loss mechanisms”. Precision farming appears to offer some solutions to the problem.

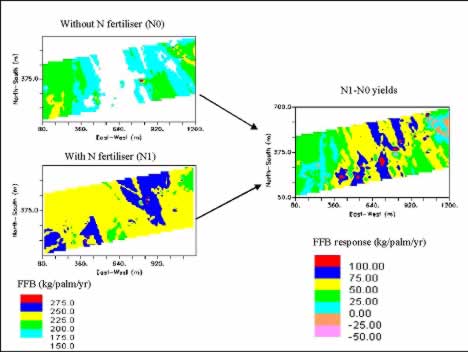

Classical fertiliser response trials on different soil types showed highly variable FFB yield responses to N, P and K fertilisers, ranging from 0 to over 100 %. These variations could be partially reduced with management zoning of the fields and correct fertilisation (Goh et al. , 1999). However, the real opportunity to optimise fertiliser inputs lies in the understanding of the large variation in fertiliser responses within the same soil series and similar terrain as shown in Table 7. In a first attempt, we have used the plots with and without nitrogen applications in a classical fertiliser response trial (about 25 ha) as sampling points for generation of yield maps by kriging. Results showed that the yield response to nitrogen varied spatially across the trial site (Figure 13). They ranged from good FFB yield response of more than 50 kg/palm/yr in the central portion of the field to poor or negative response in the eastern and western parts. These results might be partially explained by the localised high soil N contents and the presence of a thin layer of laterites in the central portion which hinders root development leading to higher N response. This study indicates that differential N input is probably more cost effective and environment friendly.

Table 7: FFB yield responses to 1 kg Ammonium sulphate (AS) applied per palm per year and corresponding yield levels at non-limiting rates of all other fertilisers in trials on some sedentary soils in Malaysia

| Soil series |

N1 response (t/ha/yr FFB) |

N1 yield |

N2 response (t/ha/yr FFB) |

N2 yield |

| Batu Anam |

0.53 |

28.06 |

0.68 |

29.57 |

| Batu Anam |

1.46 |

22.39 |

1.78 |

26.41 |

| Batu Anam |

2.56 |

18.14 |

1.24 |

22.85 |

| Batu Anam |

2.40 |

17.53 |

1.49 |

21.44 |

| Munchong |

1.33 |

23.70 |

0.47 |

24.60 |

| Munchong |

1.02 |

30.40 |

0.46 |

32.13 |

| Munchong |

-0.65 |

27.59 |

-0.75 |

25.40 |

| Munchong |

0.54 |

25.95 |

0.43 |

27.09 |

| Rengam |

1.38 |

25.03 |

0.72 |

27.39 |

| Rengam |

3.46 |

23.81 |

1.22 |

29.08 |

| Rengam |

-0.88 |

23.04 |

-1.35 |

22.28 |

| Rengam |

1.92 |

24.31 |

0.98 |

29.59 |

| Rengam |

0.78 |

26.49 |

0.56 |

27.70 |

| Rengam |

0.82 |

27.19 |

0.64 |

28.50 |

Source: Chew (1998) who adapted it from Foster et al . (1985)

Figure 13: Spatial FFB yield response of oil palm on Kumansi Family soil to N fertilisers

Apart from getting the fertiliser rates right and applying them in the correct places, timing of fertiliser applications holds the most promise for improving efficiency. This is because run-off and soil erosion are the most important pathways for soil and fertiliser nutrient losses. Both processes are driven by rainfall which is difficult to predict in the tropics. However, using expert system and artificial intelligience we have developed a package which predicts the best months to apply fertilisers taking into account the fertiliser properties, agronomic data such as palm age and nutritional status, soil data such as terrain and consistency, management resources, risk management and weather. The present management system including the size of fertiliser store generally does not allow the applications of different fertilisers in different fields in the same month or to apply the fertilisers for each field in the few best months available (problem with labour resource allocation) unless fertiliser applications are fully mechanised. Hence, the program also compares the predicted best months to apply fertilisers with the actual recommended months of applications to determine the potential loss in fertiliser efficiency (Table 8) which can be corrected with higher fertiliser rates, albeit at a “financial loss”.

Table 8: Scheduling of fertilisers for the oil palm plantations using expert system

| Manuring Block | Month/yr | Fertiliser type |

Rate (kg/palm) |

Suitability of month | Remarks |

| 1 PR97A 2 | Jul-98 | AS |

0.75 |

Good | – |

| Aug-98 | AA2 |

1.00 |

Fair | Maximum rate | |

| Sep-98 | KS |

1.25 |

Poor | – | |

| Nov-98 | AA2 |

1.00 |

Poor | Maximum rate | |

| Dec-98 | JRP |

3.50 |

Poor | – | |

| Jun-99 | MOP |

1.25 |

Good | – | |

| 1 PR97A 3 | Jul-98 | AS |

0.75 |

Good | – |

| Aug-98 | AA2 |

1.00 |

Fair | Maximum rate | |

| Sep-98 | JRP |

3.50 |

Poor | – | |

| Nov-98 | AA2 |

1.00 |

Poor | Maximum rate | |

| Jun-99 | MOP |

1.25 |

Good | – |

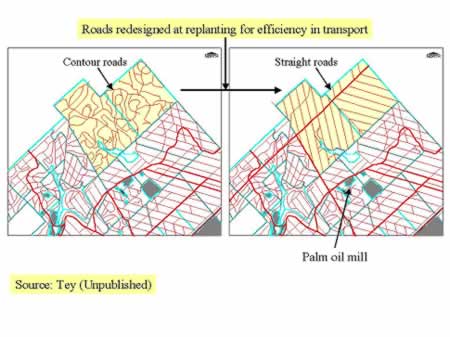

c) Infrastructure

In a good oil palm plantation of 2000 ha, there are approximately 200 km of roads to transport about 50000 tonne of FFB to the mill each year. DEM coupled with decision theory such as shortest path and network with constraints e.g. setting maximum slope of the road at 10% can be used to re-design the road system for more efficient transport of FFB to the mill as shown in Figure 14 (Tey, Unpublished).

Figure 14: Redesigning road system in an oil palm plantation using DEM for efficient transport of FFB, workers etc

Identify areas for replanting and planting

Emmott et al . (1997) stated that “If replanting is a key issue in plantation crops, then identifying where yield improvements can be achieved in order to realise a satisfactory return on investment might be appropriate area for precision farming”. This is probably true in Peninsular Malaysia where the oil palm is getting older and probably past its prime productivity due to management difficulty in maintaining sufficient leaf area index (Goh and Chew, 2000), harvesting standards and collection of loose fruits. The potential yield loss could be examined by comparing the actual yield obtained from the field against its site yield potential, which can be estimated using ASYP model as discussed earlier. The yield gaps may then be classified and displayed on GPS maps to form a basis for strategic decision (trade-off) on replanting program of the company rather than to use an arbitrary yield level such as below 18 t/ha/yr which varies with the palm oil price or at palm age of say 25 years old (Goh et al ., 2000).

Similar approach can be taken to decide on planting or land conversion to oil palm and avoid unsuitable areas such as steep hills and swamps (Goh et al ., 1997).

Monitoring and assessment of results

One of the cornerstones of precision farming is to precisely monitor and assess the agricultural enterprise at a local and farm level (Blackmore, 1994). The oil palm industry has religiously collected agronomic and management data at the field level where possible. However, to quote Gohet al . (1999) “Of late, there is a discernible move towards larger manuring blocks in the estates with many of them exceeding 100 ha. The main reasons for this are unknown although the undertone is that management will be easier especially for large estates. Such practice, which is a form of sweeping generalisation, is definitely wrong and will make a mockery out of fertiliser management. It can also easily negate the huge investments in cost, time, manpower and equipment in the preparation of precise fertiliser recommendations”. Similarly, yield data are being combined from many fields rendering them almost useless for assessment purposes. This need not happen if we use remote sensing, GIS, GPS and electronic gadgets such as Palm organisers to collect data digitally at the estate level and adapt information technology such as decision support system to store and collate data and report the results at appropriate scales for the management.

Accurate and precise maps and area of each field are essential because most productivity figures for assessment of results and performances are based on per area (hectare) basis. In the absence of expensive land surveys, GPS and GIS mapping can provide precise field sizes apart from road, soil and terrain maps (Chew, 1998). Chew (1998) also reported that errors in hectareage commonly exceeded 10% in the plantations (Table 9).

Table 9: Differences in declared hectareages in individual blocks in oil palm plantations after GPS mapping

| Estate | Area (Ha) |

Total number of blocks |

Ha difference (%) |

||||

|

< 2 |

2-5 |

6-9 |

10-15 |

>15 |

|||

| 1 |

639 |

7 |

1 |

– |

– |

5 |

1 |

| 2 |

864 |

38 |

1 |

2 |

6 |

5 |

24 |

| 3 |

974 |

16 |

3 |

7 |

3 |

2 |

1 |

| 4 |

811 |

27 |

3 |

3 |

4 |

9 |

8 |

Source: Chew (1998)

Yields in the plantations are usually estimated from bunch count numbers and average bunch weight for the fields. The number of bunches from each task (usually 1-2 ha) or platform can be recorded using a Palm organiser such as PalmPilot and electronically transferred to the database to compute harvester and field productivity quickly. Yield maps can also be generated for the purposes discussed above. With in-field mechanisation and collection of FFB, the prospects for more precise yield monitoring at finer scale are good (Chew, 1998) and should be encouraged.

Precision Farming: What is Precision Farming

[addw2p name=”precisionFarming”]

“Precision farming” is the new term coined for farming practices which were variously described as “prescription farming”, “site-specific” practices, “variable rate technology” etc previously (Chew, 1998). Notwithstanding the many connotations, the basic philosophy of precision farming is to measure and manage variabilities such as yield, soil, pest and weed across the fields (Larscheid et al. , 1997) in order to enhance efficiency in the management of agricultural practices in the cropping system for optimum productivity, product quality and economic returns, and minimise environmental impact and agricultural risk. It therefore prescribes applications of what are only required to achieve the particular goal(s) at various distinct points or sites (Chew, 1998) in sufficiently fine scale in the fields. It capitalises on the advent in information technology and engineering to attain its objectives.

The five core components or processes of precision farming (Blackmore and Larscheid, 1997) are:

- Measuring variability

- Analysing variability

- Decision-making

- Differential actions

- Assessment of results

Measuring and analysing variability form the keystones of precision farming. They attempt to establish the permanent field characteristics that influence production and yield maps for as many years as possible (Blackmore and Larscheid, 1997). These characteristics or factors are recorded at precise locations over time to enable the study of spatial and temporal variabilities. The existence of these variabilities particularly yield and the understanding of them provide an opportunity for precision farming. In fact, if they do not exist then a uniform management system is both the cheapest and most effective management strategy and precision farming is redundant (McBratney and Taylor, 1999). In analysing variability, it is common to produce maps which show spatial trend, stability of the spatial characteristics such as yield and management (classified) zones for similar inputs.

Recording spatial data and plotting maps will be meaningless unless we can quickly retrieve the data and translate them into information and knowledge for use in improving the production system. This falls into the area of a decision support system (Goh et al. , 1997) which can incorporate inter alia crop models, artificial intelligence, data mining tools and information technology to examine whether variable actions in specific areas of the fields are warranted, match the local resources and agronomic practices with the soil properties, crop requirements etc and develop different strategies from the data for the management to choose and implement in the fields. However, it should be appreciated that not all variabilities can be managed efficiently or economically because they depend very much on the nature and magnitude of the variabilities (McBratney and Taylor, 1999).

The availability of geographical information system (GIS) and global positioning system (GPS) has enabled the quick production of maps for the management to locate the problem areas precisely in the fields for differential treatments. Variable rate applicators, machinery and technology have been used in many crops such as rice, wheat, corn, soybean and other crops to apply the prescribed treatments at each site (Chew, 1998). As the costs of equipment and technology decrease, this practice will eventually become available to farmers with low value or non-strategic crops like oil palm.

It is a wise management principle to always monitor and assess the results of agricultural practices against the tactical or strategic objectives and goals of the cropping system for further actions and if necessary, the whole processes of precision farming may repeat themself. In fact, McBratney and Taylor (1999) have conceptualised the above processes for a site-specific management system as a Precision Agriculture wheel as shown in Figure 3. They also point out that precision farming is a wheel and without one of the cogs it will not succeed.

Figure 3: The Precision Agriculture wheel: Components of a site-specific crop management (SSCM) system

Source: McBratney and Taylor (1999)

The philosophy and processes of precision farming have been made possible by the advent and recent affordability of several key technologies (Chew, 1998) such as:

- Personal computers

- GPS technology which reads signals continuously available from satellites enabling near pin-point horizontal and vertical accuracy

- Remote sensing where satellite and aerial images are processed and correlated to crop characteristics

- GIS technology which manages and displays spatial data and relationships

- Variable rate application equipment with sensors and GPS to respond to field and soil variables.

Apart from hardware, the development in information technology is also essential towards the success of precision farming. The technology is needed to control the sensors for variable rate application, datalogging and transforming data into knowledge as discussed earlier.

It is increasingly recognised that precision farming is a cropping system and therefore, cannot be separated from the management system and philosophy of the farm. This is because precision farming involves capital expenditure, re-training of personnel including workers, and human perception and acceptance of new practices. McBratney and Taylor (1999) state that the concepts of Total Quality Management (TQM) and Vertical Integration (VI) in the agricultural sector are central to the precision farming philosophy. They further contend that “a farmer is concerned not only with quality at the farm gate but also the quality at the point of sale and how his product meets consumer demands. This will bring premiums and also will probably be used for environmental auditing”.

With the potential benefits, it is not surprising that interest in precision farming is now sweeping the world with many research centers being set-up to advance the technologies and introduce them to the local farming systems. Can we learn from them and apply these new tools to our advantage in the oil palm plantations?

Oil Palm: Precision Farming

[addw2p name=”precisionFarming”]

The oil palm, Elaeis guineensis, Jacq ., is a perennial tree which is extensively planted as a monoculture crop in the plantations. It was introduced into Malaysia in the late 19th century but its phenomenal growth commenced only in the mid-sixties under the crop diversification plan. From 97000 ha in 1965, the oil palm areas have increased to about 3.3 million ha in 1999 (MPOB, 2000). The annual export revenue of oil palm at about RM 18 billion between 1997 and 1999 has brought much relieve to the nation during the recent financial crisis.

However, the substantial increase in oil palm areas has not been commensurate by its productivity in terms of yield per ha. The national fresh fruit bunch (FFB) yields have stagnated at a relatively low level of 18.7 t/ha/yr (Table 1). Similar trend was obtained by the major plantation groups with annual FFB yields fluctuating between 20 and 22 t/ha/yr since 1989 (Figure 1). These yields also fell short of their site yield potentials based on experimental results. The dismal yield performances have been attributed to many factors, among them are generalised agricultural inputs and monitoring, increased field size or management unit, declining management standards, lack of skilled workers and poor understanding of agronomy, but probably also exacerbated by the planting of oil palm on soil and climatic conditions previously deemed as marginal or unsuitable and the replanting of the rubber and cocoa on hilly, poor soils to oil palm.

Table 1: Mean yield of fresh fruit bunches (FFB), crude palm oil and palm kernels in Malaysia 1975-1997

|

Year |

FFB yield (t/ha/yr) |

Crude palm oil (t/ha/yr) |

Palm kernels (t/ha/yr) |

|

1975 |

17.95 |

3.66 |

0.74 |

|

1976 |

16.16 |

3.48 |

0.71 |

|

1977 |

16.32 |

3.54 |

0.74 |

|

1978 |

16.25 |

2.95 |

0.68 |

|

1979 |

17.76 |

3.65 |

0.79 |

|

1980 |

18.72 |

3.78 |

0.81 |

|

1981 |

19.16 |

3.76 |

0.79 |

|

1982 |

19.50 |

3.83 |

0.80 |

|

1983 |

17.45 |

3.43 |

0.72 |

|

1984 |

21.80 |

4.25 |

1.19 |

|

1985 |

22.15 |

4.33 |

1.28 |

|

1986 |

22.15 |

4.41 |

1.28 |

|

1987 |

17.10 |

3.39 |

1.01 |

|

1988 |

17.52 |

3.47 |

1.04 |

|

1989 |

19.57 |

3.88 |

1.15 |

|

1990 |

18.53 |

3.64 |

1.10 |

|

1991 |

17.85 |

3.48 |

1.01 |

|

1992 |

17.83 |

3.43 |

0.99 |

|

1993 |

20.26 |

3.78 |

1.16 |

|

1994 |

18.42 |

3.43 |

1.05 |

|

1995 |

18.93 |

3.51 |

1.06 |

|

1996 |

18.95 |

3.55 |

1.06 |

|

1997 |

19.10 |

3.63 |

1.06 |

|

Mean |

18.67 |

3.66 |

0.97 |

Figure 1: Mean FFB yields and production costs of some major plantation groups in Malaysia from 1989 to 1997.

Apart from the above, the oil palm industry also faces two disconcerting scenarios: the excalating production costs since 1994 (Figure 1) and the decreasing real price trend of palm oil since 1950s (Figure 2). The likely consequence is a gradual dilution of profits in the long-term which can lead to the non-sustainability of the oil palm plantations. Since the palm oil price is generally beyond the control of the industry, we shall need to manage the production costs within acceptable limit to maintain sufficient returns to investment. The best avenues to achieve this in the labour intensive plantation business where wages have a strong influence on the production costs, are probably reducing labour requirement and raising FFB yields. In fact, it has been shown that a 1% increase in FFB yield will reduce the production costs by 0.8 to 1% (Ong, 2000; Goh and Chew, 2000).

Figure 2: Real price trend of palm oil since 1950

Source: Fry (1998)

Traditionally, the oil palm plantations have relied on large-scale extensive agricultural practices, improvement in planting materials and good management, which have served us so well in the past, to increase productivity. However, they now seem to offer few scopes for alleviating the above grave scenarios and closing the perceived large yield gaps seen in the industry over the past two decades. Therefore, as stated by Chew (1998), “It appears inevitable that we shall have to intensify and improve our planting practices by developing new techniques to increase efficiency and productivity to keep ahead of our competitors and maintain our reputation as a responsible green industry”. This strategy or approach falls within the realm of precision farming as discussed below.

This paper will attempt to provide a brief overview of precision farming, preliminary assessments of the applicability of precision farming for oil palm plantations and future work on precision farming for oil palm plantations.

Reference

Goh, K.J., Tee, B.H. and Anuar, A.R. (2000) Applicabilitity of precision farming for oil palm plantations in Malaysia. In: Seminar on Precision Farming. 16 October 2000, Universiti Pertanian Malaysia and Agricultural Institute of Malaysia, Serdang: Preprint.

Note: The full list of references quoted in this article is available from the above paper.

Fertilizer Management: Current Challenges

[addw2p name=”fertilizerMgmt”]

Some current challenges and future trend

The fertilizer management system described thus far can be regarded as traditional method commonly adopted in the oil palm plantations. It has served the industry well as evidenced by the high FFB yields, respectable returns to manuring and sustainability. But, the industry now faces many new challenges and some of them are briefly discussed below.

Labour requirements

The current plantation management system is labour intensive and many of them are deployed in manuring work. Switching to mechanical spreading of fertilizers will immediately result in tremendous saving in labour requirements but the following principal points should be noted (Chew et al ., 1994a):

• Application efficiency increases when roots system of oil palms are adequately developed and spread out

• Avoid application over eroded and compacted areas traversed by in-field vehicles which suffer severe run-off

• Limited to areas of suitable terrain and soil types which can take vehicle load

Apart from the above points to consider, there is usually a lack of control in actual fertilizer application rate with mechanical spreader since the speed of tractor is variable and the actual traverse path of the tractor is determined by the driver. Both difficulties can probably be overcome with electronic controller and GPS.

Other responses to the high labour requirements for manuring are to reduce the frequency of application to once a year e.g. the use of FELDA or AA+ Mulch TM for mature palms (Figure 1), effective sources of fertilizers, improving nutrient holding capacity of the soils and better nutrient uptake by roots. Recent results showed that applying fertilizers under the FELDA Mulch resulted in better leaf and rachis P and K concentrations of oil palms compared with broadcasting in a high rainfall region in Sarawak (Figure 2). This system reduces surface run-off and erosion of applied nutrients and avoids excessive concentration of applied nutrients at a spot. Therefore, it allows the application of fertilizers during wet weather. This method also provides better flexibility in the manuring programme and utilization of labour. However, the long-term economic returns from this system are still being evaluated.

Figure 1: Experimental testing of FELDA mulch for mature palms to reduce the frequency of fertilizer application and surface run-off losses of nutrients.

Source: Lee et al . (2008)

Figure 2: Effects of methods of fertilizer application using FELDA Mulch (FM) and broadcasting (FSP) on leaf and rachis nutrient concentrations of oil palms. Trial was layout in a high rainfall region in Lundu, Sarawak (FASSB, unpublished)

Fertilizer prices

The volatile fertilizer prices in the past two years have been described as a “perfect storm” in IFDC report, Volume 33(4), December 2008. According to the report, numerous factors converged simultaneous to cause fertilizer prices to soar and then suddenly collapse. The latter was attributed to “demand destruction” when farmers were unable or unwilling to pay two to three times the prices of early 2007. The report further stated that the situation worsened with the collapse of the global credit market, a trade recession and slowdown in world economic growth. This depressing scenario of the fertilizer market for at least the next two years is nothing new as it has happened on a number of occasions in the past although the factors causing them might vary.

The first reaction of most farmers and planters to high fertilizer prices is generally to withdraw fertilizer inputs for better cash flow. However, as advised by Dr. Ng Siew Kee in the 1970s, we should look inwards first and examine various scopes to improve fertilizer use efficiency for greater economy in fertilizer usage. This would include adapting the various methods to fully utilize the by-products in the mill on a large scale in a practical manner as another source of soil amendments and fertilizers and not fertilizer substitutes or waste products. Thus, their agronomic and economic values must be painstakingly computed as shown in Goh et al . (1999). Any potential wastage in the fertilizer management system such as luxurious fertilizer regimes for the sites, poor fertilizer quality and incorrect timing of fertilizer application must be strictly attended to immediately.

The next step is to be fully aware of the factors affecting the economics of fertilizer usage as provided by Hew et al . (1973) and Lo and Goh (1977). Some of the major factors in the computation are the base yield, fertilizer response, discount factor, prices of palm oil and fertilizers, and agricultural risk. These factors are site dependent i.e. soils, palm age, climate and their interaction with nutrients and thus, it should be the agronomist who determines the quantum and where fertilizer should be reduced to meet the company’s cash flow and anticipated profit. Ng and Goh (2003) also showed that the type of agricultural risk to be taken depends on the economic situation and cash flow of the company. Under tight cash flow or low profitability, risk preference approach is probably the best option.

In determining the fertilizer response curve, the agronomist should calculate the impact of both fertilizer withdrawal and subsequent re-application of fertilizer. An example is illustrated in the self-explanatory Figure 3 where seasonal trend has been removed.

Figure 3: Predicted effects of fertilizer withdrawal and resumption on FFB yields in Malaysia using AAR’s combinatorial model. Source: AAR (Unpublished)

The main features to note in this graph are:

• The decline in yield depends on palm nutritional status, soil fertility and time

• There is a time lapse of about a year before a linear decline in yield is observed

• The minimum yield depends on soil fertility and palm age

• The recovery rate depends on palm nutritional status

• When the palm is severely malnourished, its maximum yield is about 10% below its potential even after full recovery (Warriar and Piggott, 1973; Caliman et al. , 1994). The reason for this is still uncertain.

Reducing fertilizers or totally withdrawing them for economic reasons should always be a last resort because some yield loss will ultimately happen and the economic optimum is usually not achieved. However, it will relieve the cash flow problem of the company because fertilizer cost is the largest operational cost in managing an oil palm plantation. Thus, if fertilizer withdrawal is absolutely necessary, the following strategy might be followed but it certainly require a competent agronomist to implement it correctly:

• Select the nutrient with the least impact on FFB yield (revenue depends on prices and thus difficult to target)

• Any cheaper sources?

• Select soil types/fertility with lowest FFB yield response to the nutrient

• Select the climatic zone with least impact on FFB yield

• Select palm age category with least impact on FFB yield

• Go to step (a) until objective is achieved

This strategy will choose the category of palms for fertilizer withdrawal and the nutrients and quantity to be withdrawn that will result in the least impact on FFB yield allowing quicker recovery when the economic situation improves. It is also site-specific. Thus, it is superior to the usual strategy of many companies to cut fertilizers by a certain margin across the board, which may lead to drastic yield decline in areas with good fertilizer responses.

Sources of fertilizers

In 2007, urea accounted for more than 50 % of the world N production (excluding ammonia). This is also true in Malaysia where urea and urea-based fertilizers will take the lion share of the N market although in the oil palm industry, the converse may be true. The latter was due to the unpredictable N volatilization losses on inland soils which deter most agronomists from recommending it widely. If the N volatilization losses can be controlled to a predictable, narrow range for each environment, then it is possible to use urea as a main source of N for oil palm on inland soils whenever it is cost effective.

Currently, many methods are available to reduce N volatilization losses from urea such as urease inhibitors, S-coating (perhaps using 10% S only since Malaysian soils are generally acidic), humic acid, K and B. Also, slow release fertilizers and bio-fertilizers which are urea based are being marketed in Malaysia. We should conduct proper, well replicated trials to evaluate their effectiveness for oil palm on inland soils. Another way to stop or minimize N volatilization from urea is to apply it under AA+ Mulch TM or FELDA Mulch.

There is also a growing interest in bio-fertilizers because of the premise that the soils under oil palm are relatively sterile due to long-term fertilizer usage, and the effective microorganisms (EM) in bio-fertilizers can rejuvenate the soils leading to improve soil fertility and subsequent better productivity. Microbes are the unseen majority in soils but despite their abundance, the impact of soil microbes on ecosystem processes is still poorly understood (van der Heijden et al ., 2008). The latter workers, in their extensive review, concluded that soil microbes must be considered as important drivers of plant diversity and productivity in terrestrial ecosystems. Despite this enthusiasm, there has been no conclusive evidence that introduced EM improve crop productivity in the fields. Similarly, Blal (1989) working on the effectiveness of vesicular-arbuscular endomycorrhizas on oil palm showed that it was only effective on sterile soils. Nevertheless, this new area of research should be explored albeit at a lower level to provide data on the best route to take.

Fertilizer quality

Fertilizer quality has always been a concern to the industry. Although we have SIRIM standards, they were drawn up at a time when fertilizer prices were relatively low. With the current high fertilizer prices and the improvement in laboratory techniques and fertilizer manufacturing technology, it is perhaps logical or even warranted to call for a review of the standards particularly those related to compound fertilizers and fertilizer mixture. Also, newer experimental data are now available to assess the effectiveness of various fertilizers such as rock phosphate (Chan and Goh, 1997a, Zin et al ., 2001) which should be incorporated into the standards.

RSPO

The creation of RSPO has added another dimension to the many aspects of an agronomist’s roles because fertilizer management is part of the Principles and Criteria of sustainable palm oil under Principle 4.2. This Principle states that soil fertility should be maintained or improved to a level that ensures optimal and sustained yield by monitoring the trend of soil organic matter and net fertilizer inputs. As expounded earlier, this has always been a feature in the conventional fertilizer management system of oil palm.

Ng et al . (2004) showed that soil organic C decreased with time in the oil palm plantation during the period when the oil palm biomass was allowed to be burnt or partially burnt at replanting. However, large increases in soil organic C occurred with the current zero burnt replanting technique in the first few years. This positive change has not been traced over the life cycle of oil palm and moreover, there is currently no conclusive evidence to show that the improved soil organic C will lead to better or sustained productivity/yield of oil palm to the best of our knowledge. This provides a golden opportunity for researchers to undertake the study in order to understand the mechanism and impact of this important subject matter.

Chew et al . (1994a), Kee et al . (1995) and Ng et al . (2004) demonstrated that soil pH will decline at localised area in the oil palm agro-ecosystem such as the palm circle due to the use of acidifying N fertilizer. However, it does not appear to affect the productivity of oil palm. There is also a strong build-up of soil P and K especially in the palm circle in order to maintain adequate solution P and K for optimal uptake of these nutrients by the palms. We need to develop some methods to improve the uptake of these nutrients in the palm circles by the palms perhaps by increasing soil organic matter and/or soil pH or through soil microbes.

Chew et al. (1994a) in their review clearly showed that leaching losses of nutrients under oil palm were relatively low. This was supported by Foong (1993), Omoti et al . (1983), Schroth et al . (2000) and recent unpublished work at AAR where the latter showed non-significant difference in solution nitrate concentrations between the optimal N rate and without N input at 120 cm depth after 18 years of differential fertilizer treatments (Figure 4).

Figure 4: Leaching losses of nitrate under oil palm on an ultisol after 16 years of differential N inputs. Source: AAR (Unpublished)

Chew et al. (1994a) and Kee and Chew (1996) also showed that the off-site effect of applied nutrients, which are mainly in the forms of run-off and erosion, were generally low at less than 15% if they were applied during suitable months for fertilizer application. The major concern here is the lack of data to assess the impact of these processes in hilly areas on the environment and fertilizer use efficiency. Nevertheless, Chew et al.(1994a) concluded that the major risks to the environment arise from the following:

• At times of clearing for oil palm planting with the large release of soluble nutrients especially K from old stand of oil palm

• Over-application of fertilizer to young palms before full development of the root system or full growth when leaching losses are highest. Split fertilizer applications are very important at this stage to improve nutrient uptake efficiency.

These two aspects of oil palm cultivation are currently subjects of active research in Malaysia.

Of interest to many researchers now is the maintenance or improvement of soil quality. In fact, in highly weathered and degraded soils of the tropics, the latter is more important to sustain high yield and profitability. However, the definition of soil quality is still subject to much debate. Nevertheless, RSPO indirectly stated that soil quality includes structure, organic matter content, nutrient status and microbiological health of the soil. While the definition of soil quality may not be the most important to our industry, we should still establish quickly some practical agro-biological indicators of the soils that have significance on the fertilizer management and sustained productivity.

Climate change and variability

Climate change and its variability have existed since time immemorial. A large proportion of these changes is natural and involves geophysical processes. However, the main concern now is the rapid rate of climate change globally that is detected recently and generally attributed to anthropogenic causes. The evidences for the latter thus far especially in the long-term have been scientifically weak. In fertilizer management of oil palm, our main concerns are the impact of fertilizer use on

• greenhouse gas (GHG) emission

• soil C build-up

• energy use

In GHG emission, it is probably only relevant in “wet” soils where the risk of anaerobic conditions is higher with consequent methane and nitrous oxide emissions. Melling et al. (2006) showed that the application of urea to oil palm on deep tropical peat only resulted in a short-term emission of small amount of methane in the month of application (Figure 5).

Figure 5: Monthly CH4 flux before and after urea application at the oil palm plantation. Data represent mean ± standard error (n = 3)

Source: Melling et al. (2006)

The effect disappeared two months after urea application. This short term effect was ascribed to reduced oxidation of methane due to its inhibition by NH 4 + ion which was produced when urea hydrolysed. Urea application to deep tropical peat under oil palm has no significant effect on nitrous oxide emission (Melling et al. , 2007). Although these results showed that urea has little or no role on GHG emission from tropical peat under oil palm, further work is necessary for a firm conclusion to be made.

Fertilization has been shown to enhance the productivity of oil palm with consequent better rooting system of more than 12 t dry matter per ha. However, the sequestration of this organic matter to soil organic C in different environments is still uncertain. There is also a lack of data on C sequestration from the various sources of organic matter produced by the oil palm e.g. pruned fronds, EFB, POME and decanter cake, and the leguminous cover crops. This information has a large bearing on the C cycle of oil palm and its impact on climate change.

The energy balance of oil palm has been estimated by a few workers such as Wood and Corley (1993), Reijnders and Huijbregts (2008) and Wickeet al . (2008). However, they generally did not include the latest technology of fertilizer production which is more energy efficient (de Vries, 2008), the increasing use of locally manufactured urea based fertilizer and recycling of oil palm biomass residues and mill by-products and thus, probably grossly over-estimated the energy use in oil palm plantation. It is critical that a new life cycle analysis (LCA) of the energy balance of oil palm be made in view of the pressing need to correctly inform our buyers, consumers and NGOs with scientifically based data.

Competent agronomists

The current and future crop of agronomists has a formidable task not only to improve fertilizer use efficiency and palm oil yield but also meet the many challenges listed above and future work below. Thus, they must have the leadership and creativity to meet these challenges and the courage and commitment to pursue and persevere towards their convictions and maintain the highest standards possible. The ability to adapt to change and avoid self ego is essential if we are to maintain our edge over the competing vegetable oil crops in the long run. Also, the agronomists are now regularly requested to evaluate untested products for the plantations. They must maintain their integrity and based their decisions on scientific ground and guiding principles of soil and plant nutrition, and do not allow friendship and emotion to cloud their judgement. The other roles of agronomists were well described by Chan and Goh (1997b) and Chew and Goh (2003). The cooperation between agronomists from different organisations should continue to be fostered and joint research work initiated to solve problems of common interest. With the rapid expansion of oil palm worldwide, the number of agronomists required has also increased correspondingly and the lack of competent agronomists is becoming apparent. The industry will do well to provide the necessary atmosphere, coercion, training, facility and remuneration to attract the best and ensure that this unenviable task is under good hands.

Reference:

GOH, K.J., G, P.H.C. AND LEE, C.T.: Fertilizer Management and Productivity of Oil Palm in Malaysia

The full list of references quoted in this article is available from the above paper.

Fertilizer Management: Future Works and Research

[addw2p name=”fertilizerMgmt”]

The future work in oil palm agronomy has been well discussed by Soh et al . (2006), Kee and Goh (2006), Goh (2005), Chew and Goh (2003), Kee et al . (2003) and Chew et al . (1997) just to name a few from AAR only amongst the many from other organisations in the oil palm industry over the years. It is neither our duty nor the place here to summarize these papers but to complement them.

The principles and philosophy of nutrient budget have served us well as evidenced by the high productivity of oil palm despite being largely grown on weathered, degraded soils in the tropics. Currently, the oil palm has probably the best nutrient use efficiency per tonne of vegetable oil. While the K budget can account for the optimal K rates in fertilizer response experiments, the N budget cannot explain over 30% of the N balance (Table 1) in the same set of experiments. This will require the more difficult research work on nutrient cycling and dynamics, which should yield results for further improvement of fertilizer use efficiency of oil palm. This work should include other minor nutrients and elements known to affect crop performances.

Table 1: Nutrient balance computations for commercial areas. Source: Chew et al . (1994b)

|

Commercial areas |

Soil series |

% N balance |

% K balance |

|

1 |

Tavy |

-32.5 |

+1.0 |

|

2 |

Munchong |

-38.6 |

-6.7 |

|

3 |

Tavy/Gajah Mati |

-27.8 |

+8.3 |

|

4 |

Prang/Local Alluvium |

-39.1 |

-0.3 |

|

5 |

Munchong/Tavy |

-36.3 |

-1.9 |

|

6 |

Bungor/Batu Lapan |

-30.7 |

+1.0 |

|

7 |

Munchong/Rasau |

-35.8 |

+4.5 |

|

8 |

Munchong/Holyrood |

-37.1 |

-0.9 |

|

9 |

Munchong |

-32.7 |

+14.2 |

The roles of biotic factors on palm nutrition are expected to become more prominent as we breed for truer inbred hybrids with more uniform (identical) genetic make-up on a commercial scale. Similarly, the greater use of clones and re-clones will necessitate the study of their specific or differential nutrient requirements. For example, in Clone 1, there was hardly any response to K fertilizer inputs after years of experimentation compared with Clone 2 and DxP materials (Figure 16). Similar results have been reported by Jacquemard et al . (2002) and Donough et al . (1996). Another black box in oil palm nutrition is the roles of soil microbes and biodiversity. This needs urgent studies if we are to exploit this largely unknown soil resource.

Figure 1: Differential FFB yield responses of oil palms propagated by tissue culture (clonal) and seeds (DxP) to K fertilizer in Kumansi Family soil in Sabah, Malaysia. Average yields between 2003 and 2008 were shown in the graph. Source: AAR (Unpublished)

The lack of study on physiological plant nutrition in the oil palm industry is still glaring. This deficiency must be addressed quickly to understand the various phenomena seen in the fields such as pre-mature frond desiccation, relationship between pest and diseases and palm nutrition, the root system and its mechanism for nutrient uptake, and the roles of plant nutrition in climate change amongst others; and develop new direction for studying plant nutrition and better, practical fertilizer use technology.

In the seventies and early eighties, there was much co-operation among the research organisations in Malaysia for joint research on common problems and meta-analysis of experimental data. For example, the combined analysis of fertilizer response trials from the industry by Dr. Foster and co-workers has resulted in a fertilizer recommendation system for oil palm and a set of indicators of palm health (Goh, 2005). However, newer agronomic data are now available and these experiments are conducted with later generation of planting materials and current recommended management practices on more diverse soil types and environments, which are probably more relevant to the industry today. Thus, it appears logical to conduct another meta-analysis of these newer data.

The palm oil mills should be regarded as large stores or reservoirs of nutrients/fertilizers and carbon/organic matter. The current methods to utilize these resources are still tedious, laborious, cumbersome and limited to specific areas. Furthermore, the expensive soluble nutrients such as K are probably not fully recovered. Theoretically, if all the nutrients can be recovered, the oil palm industry needs very little fertilizers because our main produce, palm oil, does not contain much nutrients. While we are not suggesting turning the palm oil mill into fertilizer factory, scrutinizing for new technology to recover these nutrients and carbon and making them user friendly e.g. granulation or liquid fertilizers are urgently needed. In fact, a growing number of agronomists worldwide has the opinion that producing higher yields requires not only advanced genetics but good agronomic management which includes good plant nutrition utilizing both organic and inorganic nutrient sources (Roberts, 2009). Apart from the above impact, it will have huge implications on carbon credit, carbon balance, energy balance, sustainability and a host of other initiatives related to global palm oil trade.

Research Work

Research work on precision agriculture in oil palm has commenced in the 1990s and its potential applications have been demonstrated (Goh et al. , 2000). For example, the generation and combination of yield maps of plots with and without nitrogen application in a classical fertilizer response trial (about 25 ha) using geostatistical methods showed strong spatial yield responses to nitrogen (Figure 2). They ranged from good FFB yield response of more than 50 kg/palm/yr or 6.6 t/ha/yr in the central portion of the field to poor or negative yield responses in the eastern and western parts. This information can be transformed into management zone for site-specific management (Anuar et al ., 2008). Further work is needed to exploit this technology for improved effectiveness and efficiency of inputs leading to better productivity and profitability.

Figure 2: Spatial FFB yield response of oil palms on Kumansi Family soil to N fertilizers

Source: Goh et al . (2000)

The oil palm environments comprise numerous elements or growing conditions where their interplays have a strong impact on the yield response to fertilizer inputs. For example, Kee and Chew (1993) demonstrated that the N rate may be reduced by half under irrigated compared with non-irrigated oil palm in an area with monsoonal climate (Figure 4). This was attributed to better nutrient uptake under adequate soil water throughout the year ensuring optimal palm nutritional status at most times with consequent fuller expression of FFB yields. Similarly, FELDA Agricultural Services Sdn Bhd. (FASSB) clearly showed that the FFB yields of oil palm under irrigated condition in a dry region were consistently higher (35% or 45 t/ha over five years) than non-irrigated condition given the same fertilizer regime (Figure 3). These results indicate that we may need a series of multi-factorial trials to decipher and understand the role of each growing condition on fertilizer response and to provide the recommended set to the planters to implement for best results. In fact, it is of utmost importance that the agronomists identify these conditions and design farming system that optimises the fertilizer use efficiency.

Figure 3: Effect of irrigation on N response of oil palm in a wet monsoonal climate in Malaysia

Source: Kee and Chew (1993)

Figure 4: Effect of fertilizer (N1P1K1) on oil palm yields in a dry region under irrigated and non-irrigated (FASSB, unpublished)

Technology, techniques and equipment are now available and there are hardly any reasons why these studies cannot be undertaken successfully. What is needed is creativity and ingenuity to solve our problems. As published by The Sunday Star, the local newspaper on 5 th April 2009, “Science triumphs common sense when it really matters”. Thus, the future of effective fertilizers, fertilizer use efficiency and fertilizer management, and the consequent productivity of oil palm reside in continuous generation of new applicable sciences, adaption of new technologies and designing new methods to implement them correctly and efficiently, and reducing the uncertainties related to fertilizer management.

Reference:

GOH, K.J., G, P.H.C. AND LEE, C.T.: Fertilizer Management and Productivity of Oil Palm in Malaysia

The full list of references quoted in this article is available from the above paper.

Fertilizer Management: Fertilizer Efficiency

[addw2p name=”fertilizerMgmt”]

MAXIMIZING FERTILIZER USE EFFICIENCY

I Assessment of nutrient use efficiency

Three basic questions must be answered in all assessments of fertilizer use efficiency:

- How much of the nutrients applied are taken up by the crop?

- How much additional yield is obtained for each additional unit of nutrient uptake?

- To what extent can the crop benefit from the nutrients not recovered by the crop during the period of assessment?

There are five indices that can be used to assess nutrient use efficiency.

Partial factor productivity (PFP)

PFP answers the question: How much yield is produced for each kg of fertilizer nutrient (FN) applied?

PFPFN = kg bunch kg-1 fertilizer nutrient (FN) applied:

PFPFN = BY+FN / FN (1)

where BY+FN is the bunch yield (kg ha-1) and FN is the amount of fertilizer nutrient applied (kg ha-1).

Because BY at a given level of FN represents the sum of yield without fertilizer inputs (BY0FN ) plus the increase in yield from applied fertilizer (ΔBY+FN),

PFPFN = (BY0 FN + ΔBY+FN) / FN (2)

or

PFPFN = (BY0 FN / FN) + (ΔBY+FN / FN) (3)

and by substitution with equation (5):

PFPFNFN = (BY0 FN / FN) + AEFN (4)

where AE+FN is the agronomic efficiency of applied fertilizer nutrients (see below).

Equation 4 shows that PFPFN can be increased by increasing the uptake and use of indigenous soil-N resources (measured as BY0FN) and increasing the efficiency of applied fertilizer nutrient use (AEFN).

Agronomic efficiency (AE)

AE answers the question: How much additional yield is produced for each kg of fertilizer nutrient (FN) applied?

AEFN = kg bunch yield increase kg-1 FN applied (often-used synonym: nutrient use efficiency):

AEFN = (BY+FN – BY0 FN) / FN (5)

where BY+FN is the bunch yield in a treatment with fertilizer nutrient application; BY0 FN is the bunch yield in a treatment without fertilizer nutrient (FN) application; and FN is the amount of fertilizer nutrient applied, all in kg ha-1.

AEFN represents the product of the efficiency of nutrient recovery from applied nutrient sources (= recovery efficiency, REFN) and the efficiency with which the plant uses each unit of nutrient acquired (= physiological efficiency, PEFN):

AEFN = PEFN x REFN (6)

Both REFN and PEFN thus contribute to AEFN, and each can be improved by crop and soil management practices, including general crop

management practices and those specific to nutrient management, e.g. a more balanced N:P:K ratio or improved splitting and timing of nutrient applications (see Table 2 and 3).

Because AEFN = PEFN x REFN, it is necessary to quantify the relative contribution of each component to explain measured differences in agronomic efficiency that result from different nutrient or crop management strategies.

Recovery efficiency (RE)

RE answers the question: How much of the nutrient applied was recovered and taken up by the crop?

REFN = kg fertilizer nutrient taken up kg-1 fertilizer nutrient applied:

REFN = (UN+FN – UN0 FN) / FN (7)

where UN+FN is the total palm uptake of fertilizer nutrient measured in aboveground biomass in plots that receive applied fertilizer nutrient at the rate of FN (kg ha-1); and UN0 FN is the total nutrient uptake without the addition of fertilizer nutrient.

REFN is obtained by the ‘nutrient difference’ method based on measured differences in plant nutrient uptake in treatment plots with and without applied nutrient (Equation 7). Recovery efficiency of applied nutrient is estimated more accurately when two treatments with a small

difference in the application rate are compared:

REFN = (UNFN2 – UNFN1) / (FNFN2 – FNFN1) (8)

where REFN is the recovery efficiency (kg nutrient uptake kg-1 nutrient applied); UN is the total nutrient uptake in bunches, fronds and trunk (kg ha-1); and FN is the amount of fertilizer nutrient added (kg ha-1) in two different nutrient treatments (FN2 and FN1) e.g. FN2 receiving a larger nutrient rate than FN1.

REFN is affected by agronomic practises and rainfall (Table 2)

Physiological efficiency (PE)

PE answers the question: How much additional yield do I produce for each additional kg of nutrient uptake?

PEFN = kg bunch yield increase kg-1 fertilizer FN taken up:

PEFN = (BY+FN – BY0 FN) / (UN+FN – UN0 FN) (9)

where BY+FN is the bunch yield in a treatment with fertilizer nutrient (FN) application (kg ha-1); BY0 FN is the bunch yield in a treatment without fertilizer nutrient (FN) application; and UN is the total uptake of fertilizer nutrient (kg ha-1) in the two treatments.

PEFN represents the ability of a plant to transform a given amount of acquired fertilizer nutrient into economic yield (oil or bunches) and largely depends on genotypic characteristics such as the bunch index and internal nutrient use efficiency, which is also affected by general crop and nutrient management (Table 2).

Internal efficiency (IE)

IE answers the question: How much yield is produced per kg fertilizer nutrient (FN) taken up from both fertilizer and indigenous (soil) nutrient sources?

IEFN = kg bunch kg-1 FN taken up:

IEFN = BY / UN (10)

where BY is the bunch yield (kg ha-1), and UN is the total uptake of fertilizer nutrient (kg ha-1).

This definition of IEFN includes FN taken up from indigenous and fertilizer sources. IEFN largely depends on genotype, harvest index, interactions with other nutrients and other factors that affect flowering and bunch formation.

II Implementation of nutrient use efficiency assessment in oil palm fertilizer experiments

In annual crops, destructive sampling methods can be used to measure nutrient uptake in fertilized and unfertilized plots in each crop season and fertilizer nutrient use efficiency can then be calculated by difference (Dobermann and Fairhurst, 2002). The relative ease with which this can be carried out explains why in grain crops, measurement of nutrient use efficiency is standard practice when analyzing data from field fertilizer experiments. Destructive sampling cannot be used in oil palm fertilizer experiments, however, because it is costly and precludes the possibility of further measurements in the experiment. For this reason, Fairhurst (1996) and Fairhurst (1999) devised a nondestructive approach to measure nutrient uptake, based on standard methods for estimating above ground biomass production in trunk, leaf, bunches (Corley et al., 1971, Appendix 6) combined with tissue analysis. Nutrient uptake is calculated from the nutrient concentration and the amount of biomass produced (kg ha-1 yr-1) respectively in the trunk, leaves, and bunches, and nutrient use efficiency is measured by comparing nutrient uptake in different treatments in fertilizer experiments.

Differences in nutrient use efficiency between plantations, blocks, single palms or fertilizer sources are explained by a range of factors (Table 2). The goal of a good field management is to maximize uptake by identifying possible limiting factors and implementing remidial measures.

These methods were used to assess nutrient use efficiency in six fertilizer trials at Bah Lias Research Station (BLRS) (Prabowo et al., 2002). Preliminary results from one year of measurements indicate recovery efficiencies of 19–36% (N), 7–29% (P), 29–70% (K) and 10–60% (Mg) (Table 1). Large differences in RE were measured for different fertilizer sources of P and Mg fertilizer and RE was much greater when these nutrients were supplied in soluble forms respectively as TSP and kieserite (Table 1).

Table 1. Recovery of nutrients from mineral fertilizers in five fertilizer experiments in North

Sumatra, Indonesia (after Prabowo et al., 2002).

In almost all cases, RE was greater for each nutrient when other nutrients were supplied in non-limiting amounts. RE was smaller in Trial 231 where high rainfall resulted in large fertilizer nutrient losses in surface water runoff and eroded soil (Prabowo et al., 2002). In Trial 231 RE was >100% for K where yield was less than 23 t ha-1. This suggests that palms were able to use soil indigenous K more efficiently after K deficiency had been corrected.

The separation of AE into its components of RE and PE provides the means to identify problems in fertilizer response experiments. For example it may be possible to achieve large values for RE but low values for PE result in low values for AE. Field management factors can be separated into those affecting RE and PE (Table 2). For example, RE may be large in a fertilizer treatment but a low value for PE is caused by inter palm competition and the genetic characteristics of the planting material.

Table 2. Examples of factors affecting and physiological efficiency (PE) and recovery

efficiency (RE) of fertilizer nutrients in oil palm.

Table 3. Effect of fertilizer placement on bunch yield in Malaysia.

Reference

Goh K.J., Rolf Härdter and Thomas F. (2003) Fertilizing for maximum return. In: Thomas Fairhurst and Rolf Hardter (eds). Oil palm: Management for large and sustainable yields. Potash & Phosphate Institute and International Potash Institute: 279-306

Note: The full list of references quoted in this article is available from the above paper.

Fertilizer Management: Computation

[addw2p name=”fertilizerMgmt”]

Nutrient balance approach

The methods to estimate the fertilizer rates, which have been described so far, are all empirical and therefore, should be used within the same environments where they have been developed. This limitation is partially overcome by methods which are based on the principles of plant nutrition. One of these methods is called INFERS (Kee et al ., 1994) which follows the nutrient balance approach and plant nutrient demand. These are the foundations of modern plant nutrition in the field, and recently have been advanced for dealing with soil nutrient depletion in African agriculture in general (Smaling et al ., 1999; Corley and Tinker, 2003). Although a number of past papers have discussed nutrient balance approach (Hew and Ng, 1968; Ng, 1977), only the INFERS model has been described briefly by Kee et al . (1994) and Corley and Tinker (2003) to illustrate the approach for oil palm.

The nutrient balance approach specifically attempts to balance the nutrient demand with the nutrient supply. In the oil palm agro-ecosystem, the components of nutrient demand are plant nutrient uptake for growth and production, nutrient losses through soil processes such as runoff and leaching (environmental losses) and nutrient immobilization (Figure 1). The components of nutrient supply are precipitation, pruned fronds, applied by-products such as empty fruit bunches. Any shortfall between nutrient supply and demand is met by fertilizer input. Ng (1977) considered the major variables in the nutrient balance sheet to be soil nutrient supply to the oil palm and plant nutrient demand.

Note: POME denotes palm oil mill effluent while EFB denotes empty fruit bunches

Figure 1: Nutrient cycles for nitrogen in oil palm plantations

Plant nutrient demand is the requirement for essential elements by a growing plant (Corley and Tinker, 2003). It can be separated into two processes: growth demand and deficiency demand (Tinker and Nye, 2000). The underlying theory of these two “demands” is quoted verbatim from Corley and Tinker (2003) as follows:

Nutrient amount (content) in palm, N = XW and uptake rate = ![]() =

= ![]()

where N is the total nutrient in the palm, W is the mass, X is the fractional content of the nutrient and t is time. The first term in the uptake rate represents the growth demand because the nutrient percentage remains constant as the plant grows at a rate ![]() . However, during the correction of a nutrient deficiency, the second term applies, as the weight is a constant with varying nutrient concentration. In fact, both processes probably occur at the same time. Without the differentials and ignoring change in structure of plant material, a simple approximation for the uptake is:

. However, during the correction of a nutrient deficiency, the second term applies, as the weight is a constant with varying nutrient concentration. In fact, both processes probably occur at the same time. Without the differentials and ignoring change in structure of plant material, a simple approximation for the uptake is:

X 2 (W 2 – W 1) + W 1 (X 2 – X 1) = X 1 (W 2 – W 1) + W 2 (X 2 – X 1) = X 2 W 2 – X 1 W 1

for times t1 and t2 and the meaning of the terms remains the same.